ABOUT

Erie Architectural Products (Erie AP) is a unitized curtainwall manufacturer with a hyper-focus on providing excellent customer service on complex, design-assist projects. Erie’s manufacturing center is located in Lakeshore, Ontario; their engineering office is located in Novi, Michigan. Erie AP provides a full service, turn-key solution for unitized and stick curtainwall, supplemented with operable products from their parent company, YKK AP.

IN-HOUSE DESIGN AND ENGINEERING

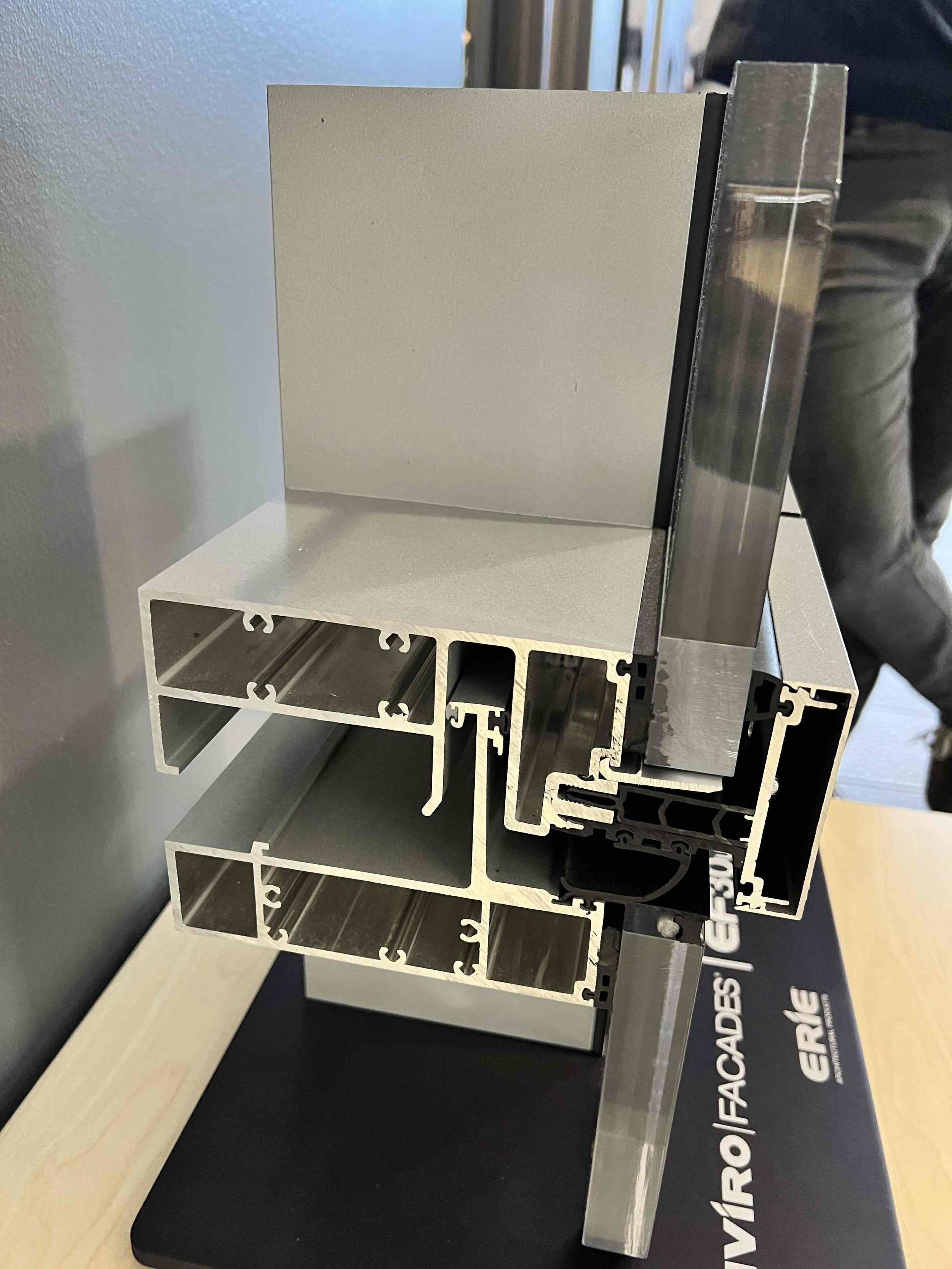

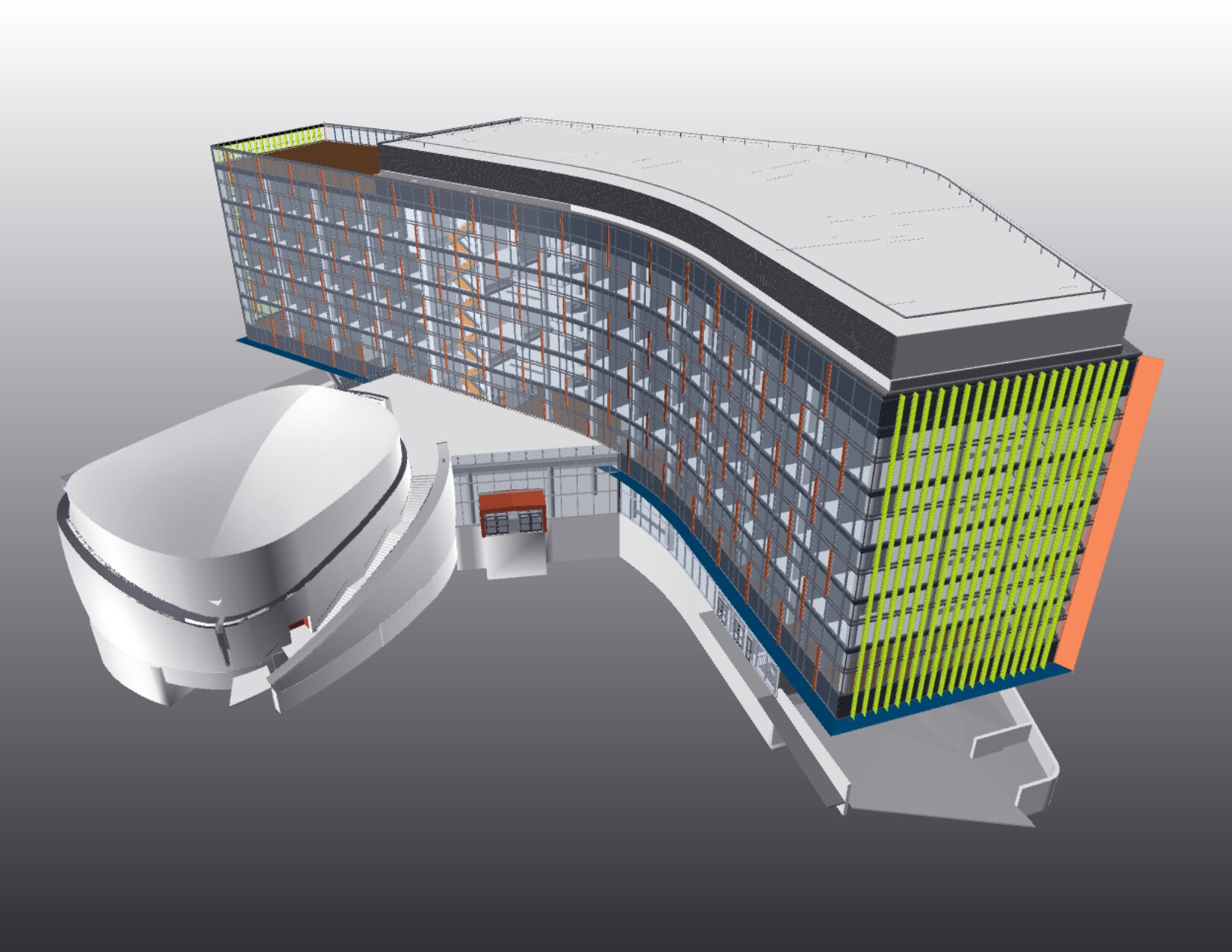

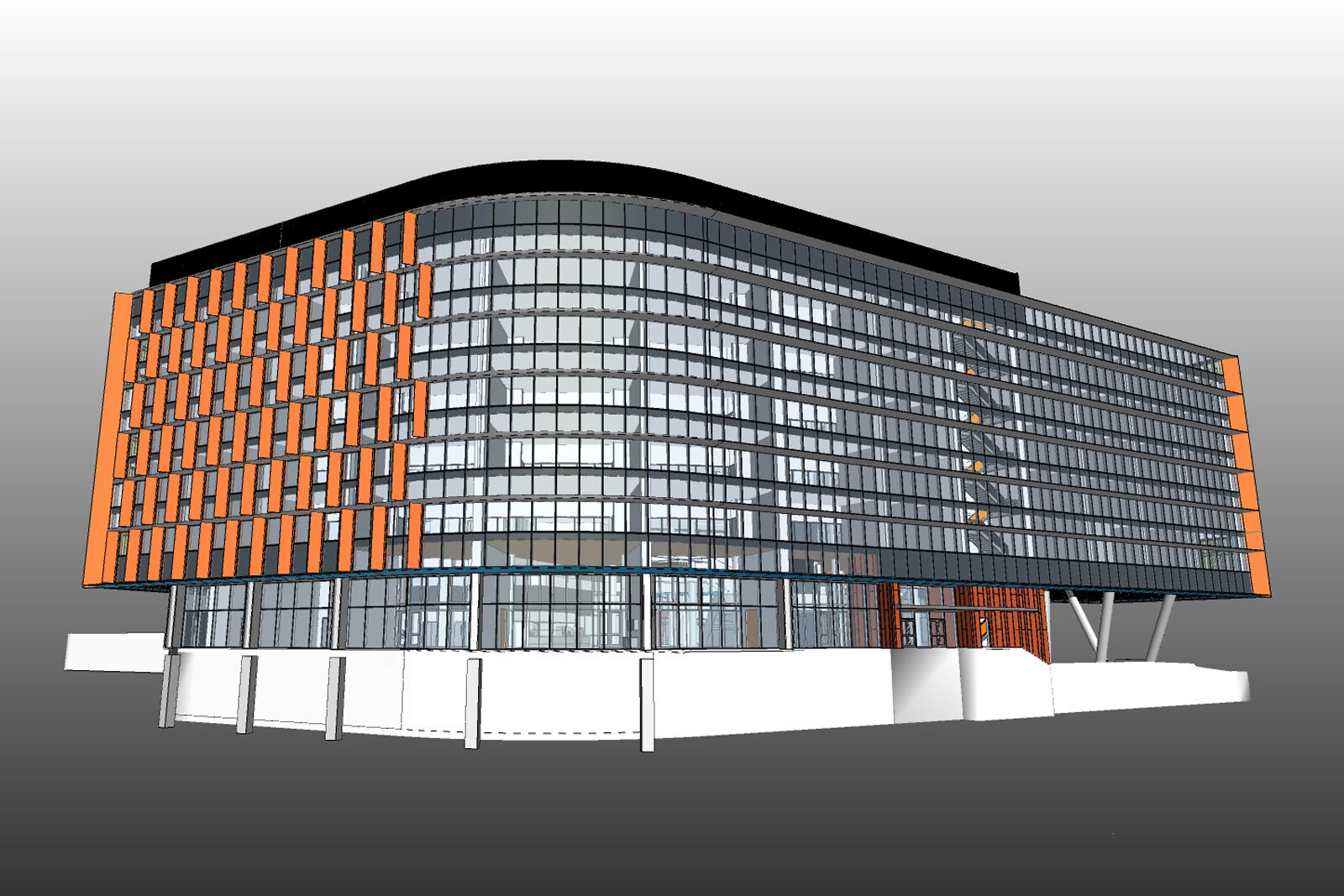

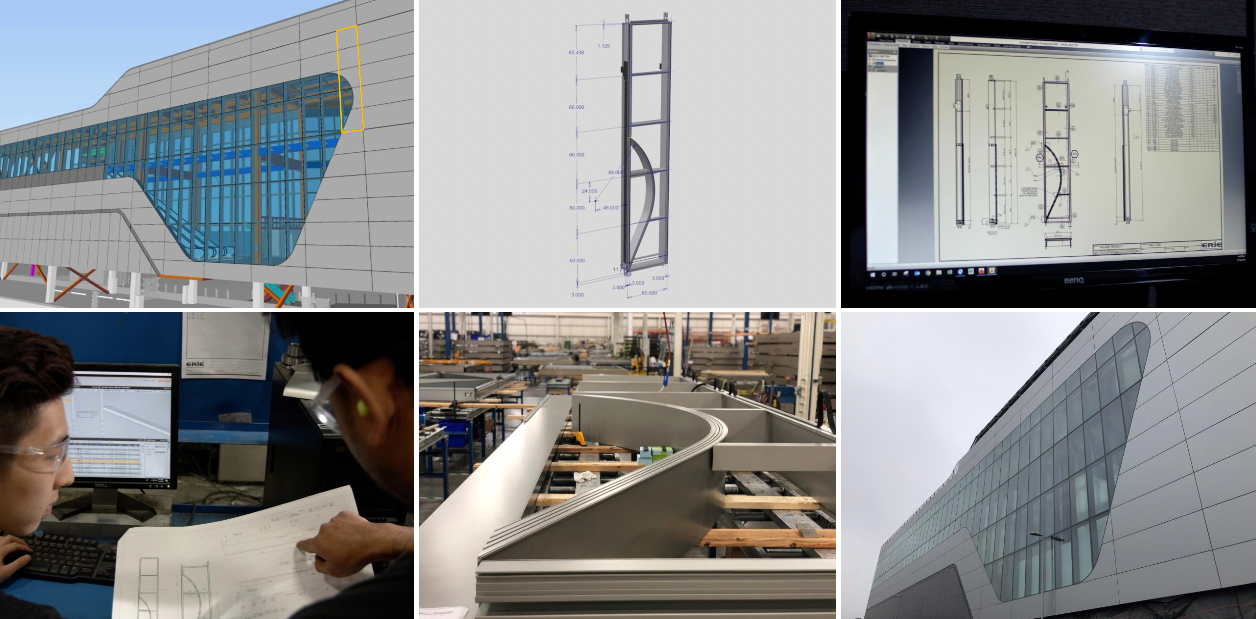

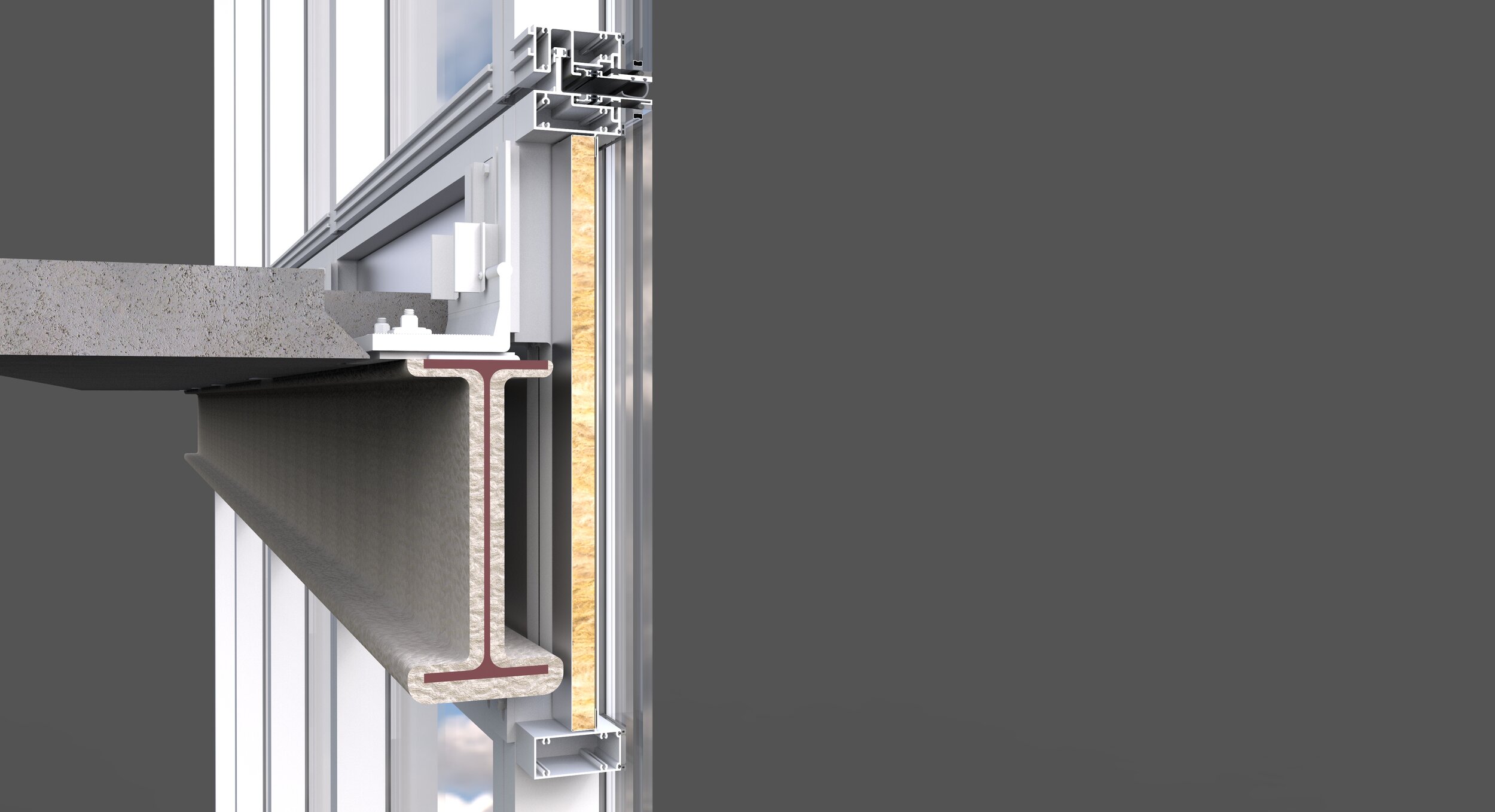

In order to provide turn-key solutions to customers, Erie has developed a robust in-house design, drafting, and engineering department. Every Erie project starts with a 3D model of the facade to coordinate and integrate with the structure, identify critical facade details, and produce submission drawings for approval. After approval, the 3D model is utilized during the Production Engineering to produce digital drawings that are imported into Erie’s machining centers for fabrication.

in-house services include:

3D MODELING / BIM

DESIGN-ASSIST (virtual & in-person)

submission engineering

PRODUCTION ENGINEERING

BLAST / SEISMIC engineering

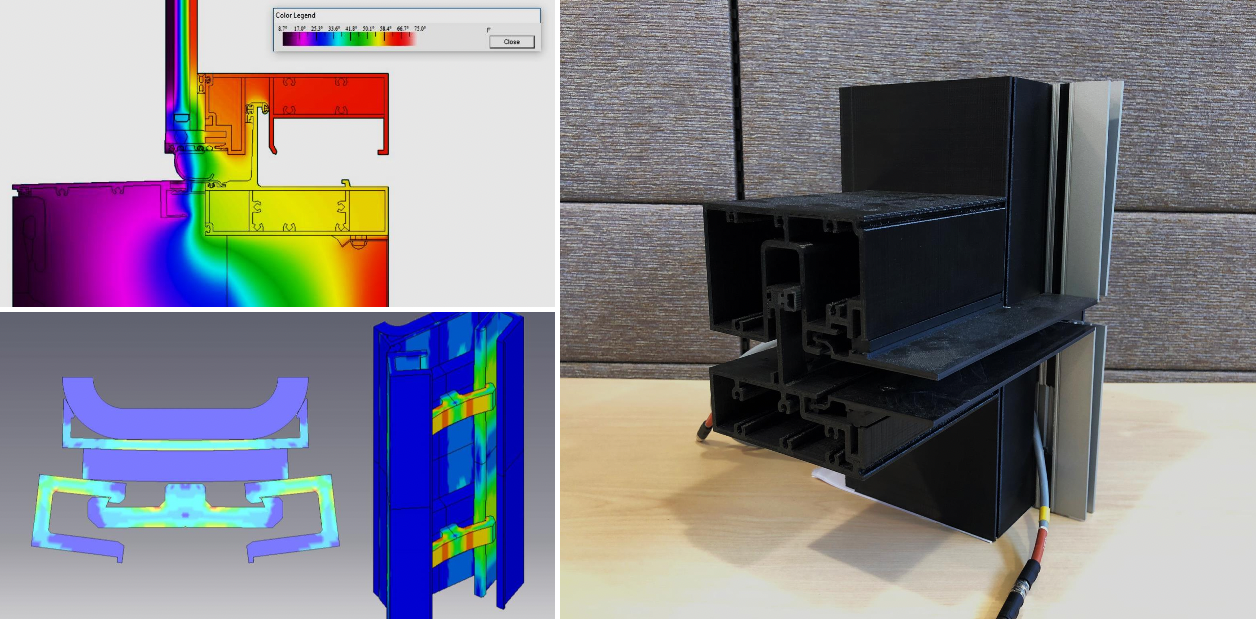

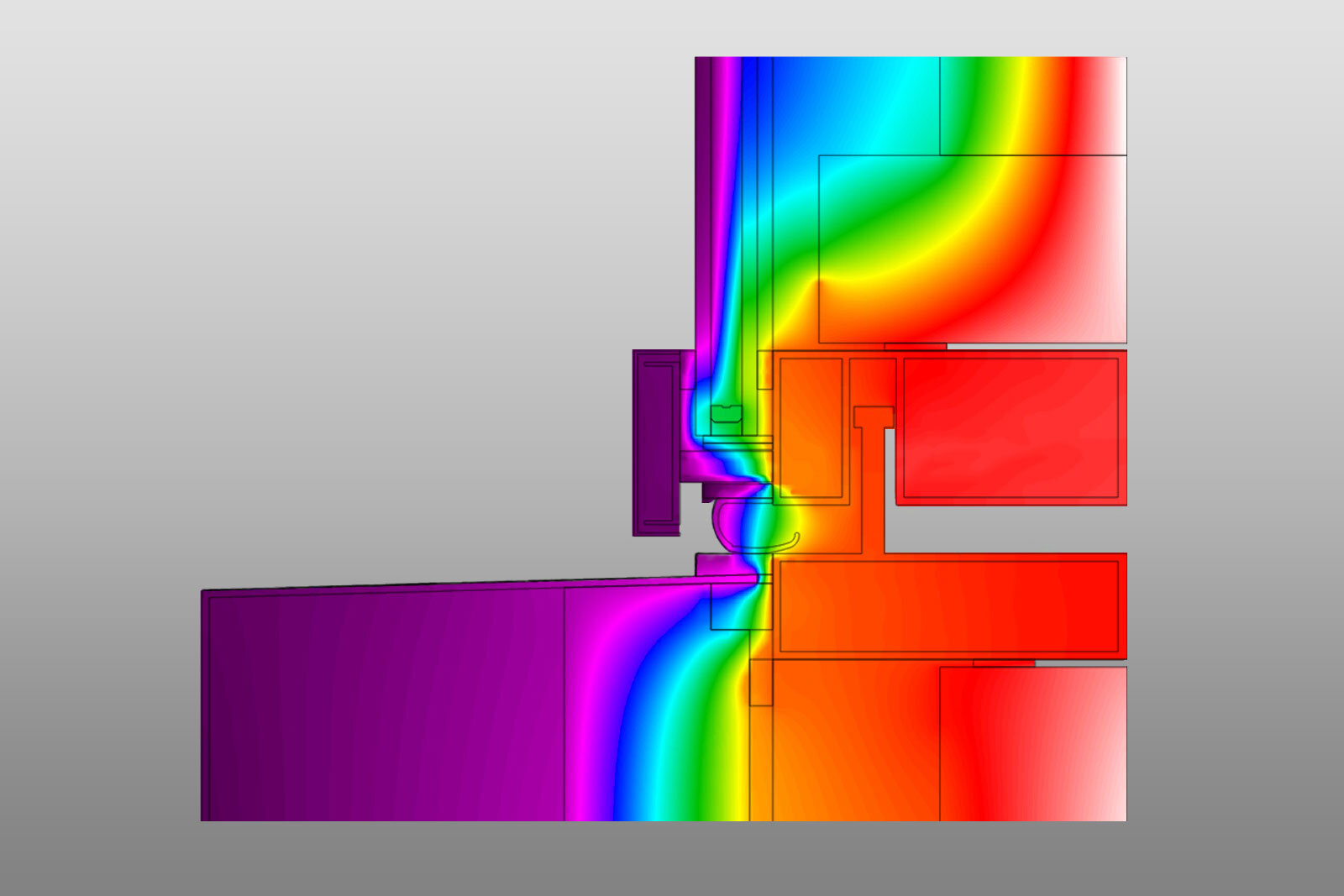

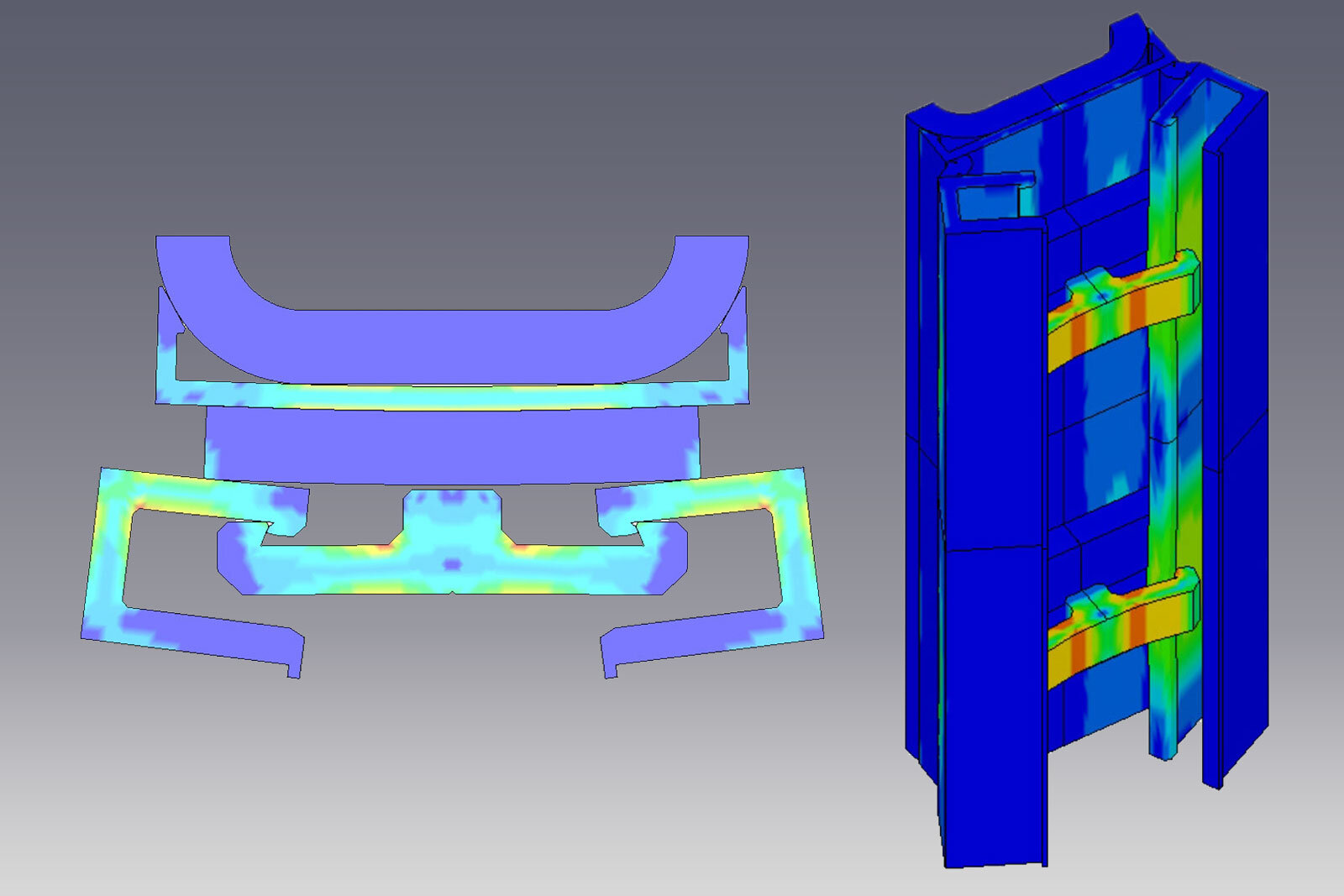

THERMAL MODELING

PROJECT MANAGEMENT

Erie’s mission is to provide “Best in Class” service for your project, which means a strong, reliable, and dependable project management team is crucial. Every Erie project is assigned a Project Executive who is involved in the project from Day 1. The Project Executive is assigned a supporting staff of Project Manager(s), Project Engineer(s), and Design Engineers as necessary to complete the project.

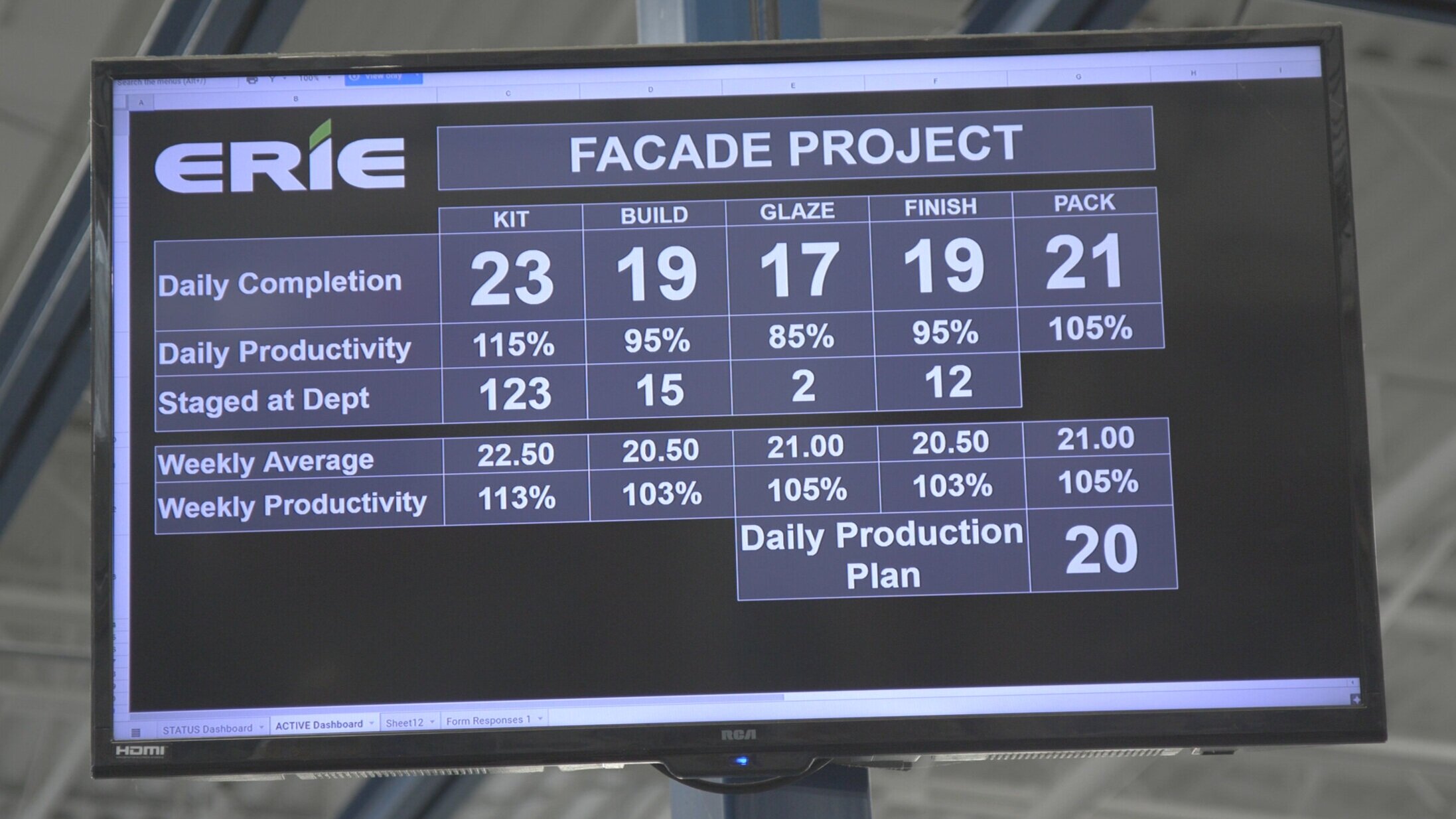

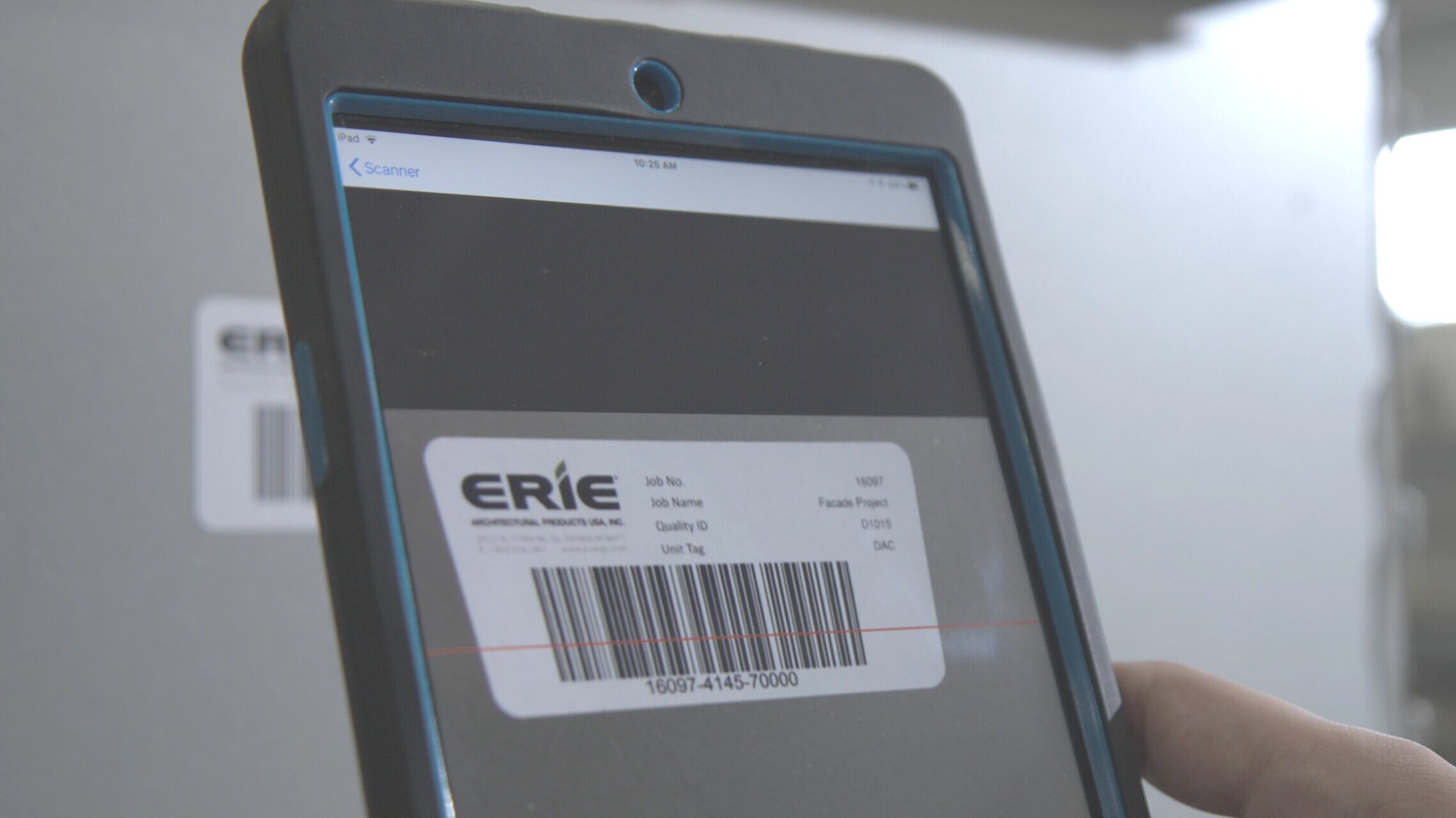

All Erie projects are designed in 3D, with an associative comprehensive schedule. This schedule allows your team to coordinate with Erie on installation sequence at both a macro and micro level. Your individual curtainwall panels are identified in the schedule according to the sequence that you need them for installation. Every panel receives a unique barcode identifier so it can be tracked throughout the project life cycle.

MANUFACTURING & TESTING

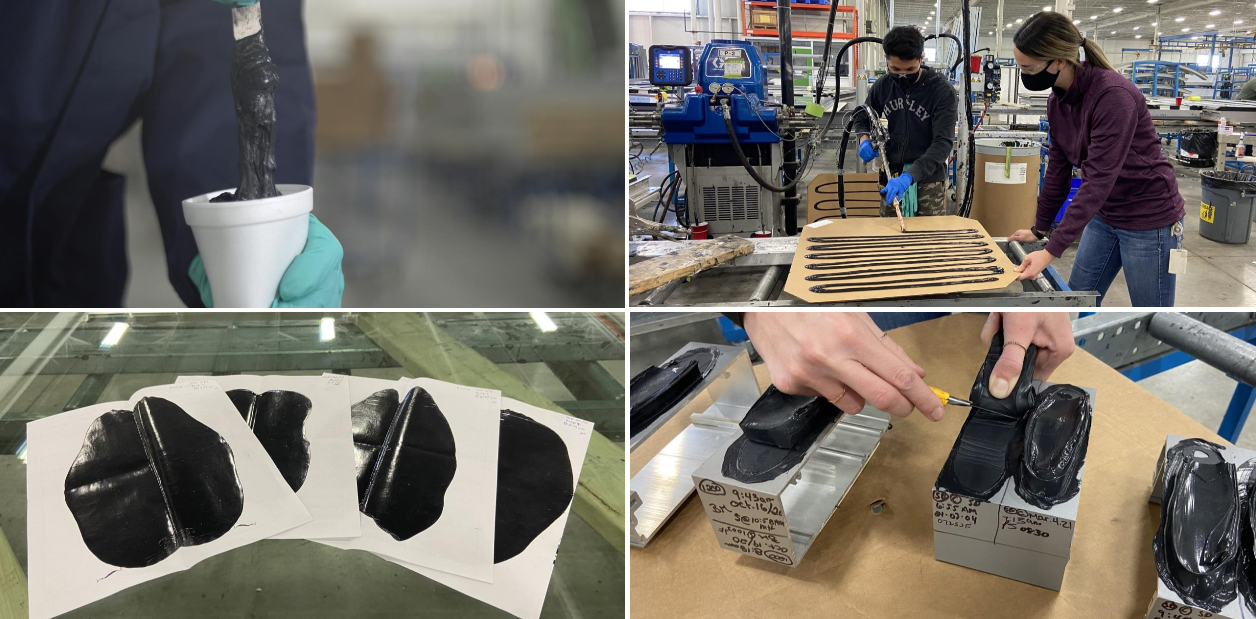

Erie’s State-of-the-Art 200k sqft manufacturing facility includes all the high end machinery, equipment, and staff that you would expect in a “Best in Class” unitized curtainwall manufacturer. Erie maintains a separate 120k sqft facility for storage of finished product and glass to manage both inbound and outbound buffers. Barcode tracking systems allow Erie to keep record of their production timelines and quality control processes implemented at each stage. Every curtainwall panel has a unique barcode identifier that travels with the panel to your job site.

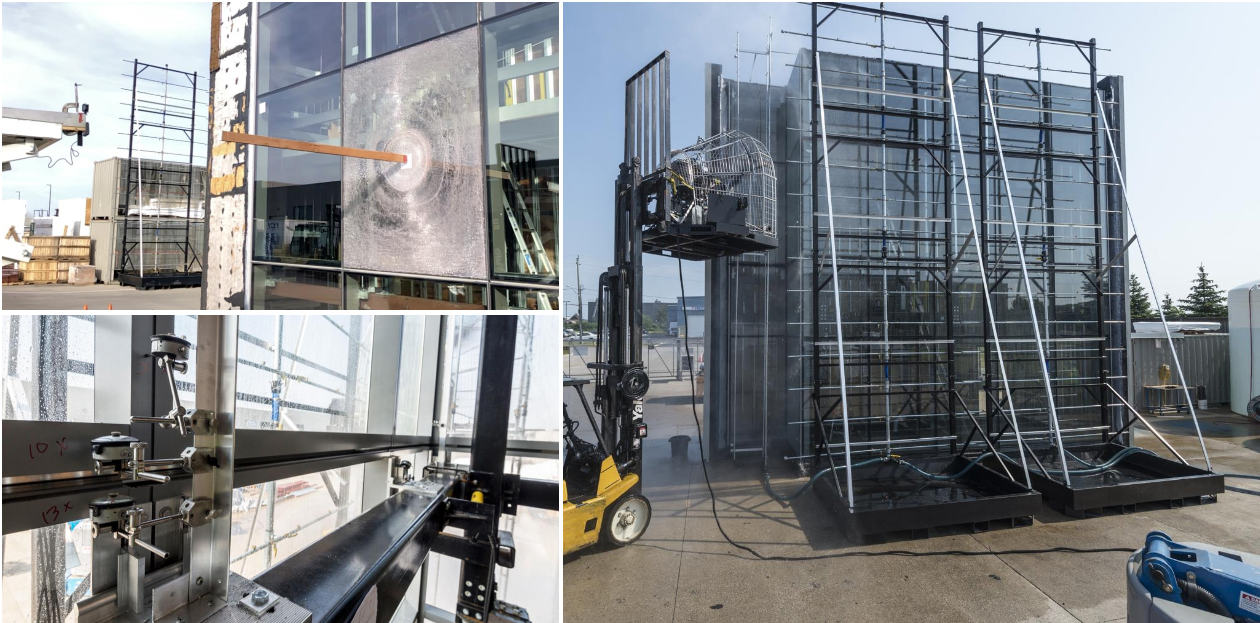

onsite research and testing center

- third party validated by intertek -

static & dynamic air/water

thermal cycling

vertical movement

seismic movement